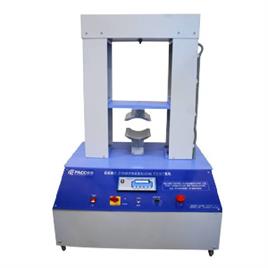

Core Compression Tester

Price ₹

30,000.00

₹30,000.00

| Model | Core Compression Tester |

| Others: | |

| Capacities | 1500Kgf |

| Display | LCD with Backlit (Digital) |

| Least Count | 0.2 Kgf |

| Model | PCCCT- 1500 |

| Motor | Crompton/ Bharat Bijlee make 1.5hp Induction motor with Gear box |

| Paint | Powder Coated |

| Power | 220V, Single phase, 50 Hz |

| Speed Range | 10mm/min to 50mm/min. |

| Test Plate Dimensions | As per the Core Specifications. |

Description

A Core Compression Tester is a precision-based quality testing machine that is used to evaluate the core crushing strength of cylindrical structures composed of paper or flexible materials. It can precisely examine the capacity of a cone or cylindrical structure to take a vertical load prior to crushing. The equipment is compact and has a user-friendly structure.The Core Compression Tester, as offered by Pacorr Testing Instruments, represents a pinnacle in quality assurance technologies for industries reliant on cylindrical packaging forms like cones or cylinders, primarily used in yarn and tissue paper sectors. This precision-based machine is crucial for assessing the vertical load capacity of these structures before crushing, ensuring that products withstand the rigors of manufacturing and usage without compromising integrity.How Core Compression Testers WorkThe tester applies a uniform vertical compressive load to the specimen, tightening the clamps until the peak crushing load is reached. This process not only helps in determining the maximum load the sample can withstand but also ensures the packaging's reliability during transport and handling. With features like a microprocessor-based display system, the tester allows for meticulous adjustments of time, load, and speed, enhancing the precision of test results.Importance in IndustryFor industries utilizing paper or flexible material in cylindrical forms, ensuring structural integrity is paramount. Poor quality can lead to production inefficiencies and product wastage. By employing a Core Compression Tester, companies can preemptively gauge product performance, significantly reducing potential losses and optimizing production lines for maximum efficiency.Choosing Pacorr Testing InstrumentsPacorr stands out for its commitment to quality and excellence in testing services, offering a vast range of precise and accurate instruments. The company's dedication to innovation and quality assurance makes its Core Compression Tester an invaluable tool for industries striving for the highest standards in product durability and reliability.Paper cones with poor quality can hamper the production line flow by getting damaged and maybe falling off. Therefore, it is of vital importance, that these structures are tested when they are rolled in for further use. This can help the user foretell the product performance way before its actual use.The Core Compression Strength Tester comes with efficient technology and features to assess the performance of paper cones or cylinders. The equipment allows the user to place widely-sized components to test with its strong gripping clamps that assure that the specimen is held safely and tight enough to ensure zero movements of the sample during the test and not too tight that it damages and crush the sample from its side edges. The microprocessor-based display system has features to set time, load and speed for the test and once it’s set one can start the procedure with just a push button. The equipment delivers uniform vertical compressive load in the specimen and the clamps start tightening the sample till it reached the peak crushing load where the sample gets crushed. This value of the load is recorded and can help the user to evaluate the quality of the product and analyze at what condition their product can fail. The tester also comes with features like inbuilt calibration and a safety switch. The calibration program allows the user to calibrate the machine before the testing procedure which is also recommended to have higher precision in test values. The safety switch on another hand ensures that the user can inhibit the test at any time they wish.

More Products from Pacorr Testing Instruments Private Limited

Pacorr Testing Instruments Private Limited Details

| GST | 09AAKCP5615P1ZP |

| Year of Establishment | 2019 |

| Nature of Business | Manufacturer and Supplier of Quality Testing Instruments |

| Number of Employees | 51 - 100 |

| Turnover | |

| Legal Status | Private Limited Company |

Tell us your Requirement

if you are interested, please fill the below details: